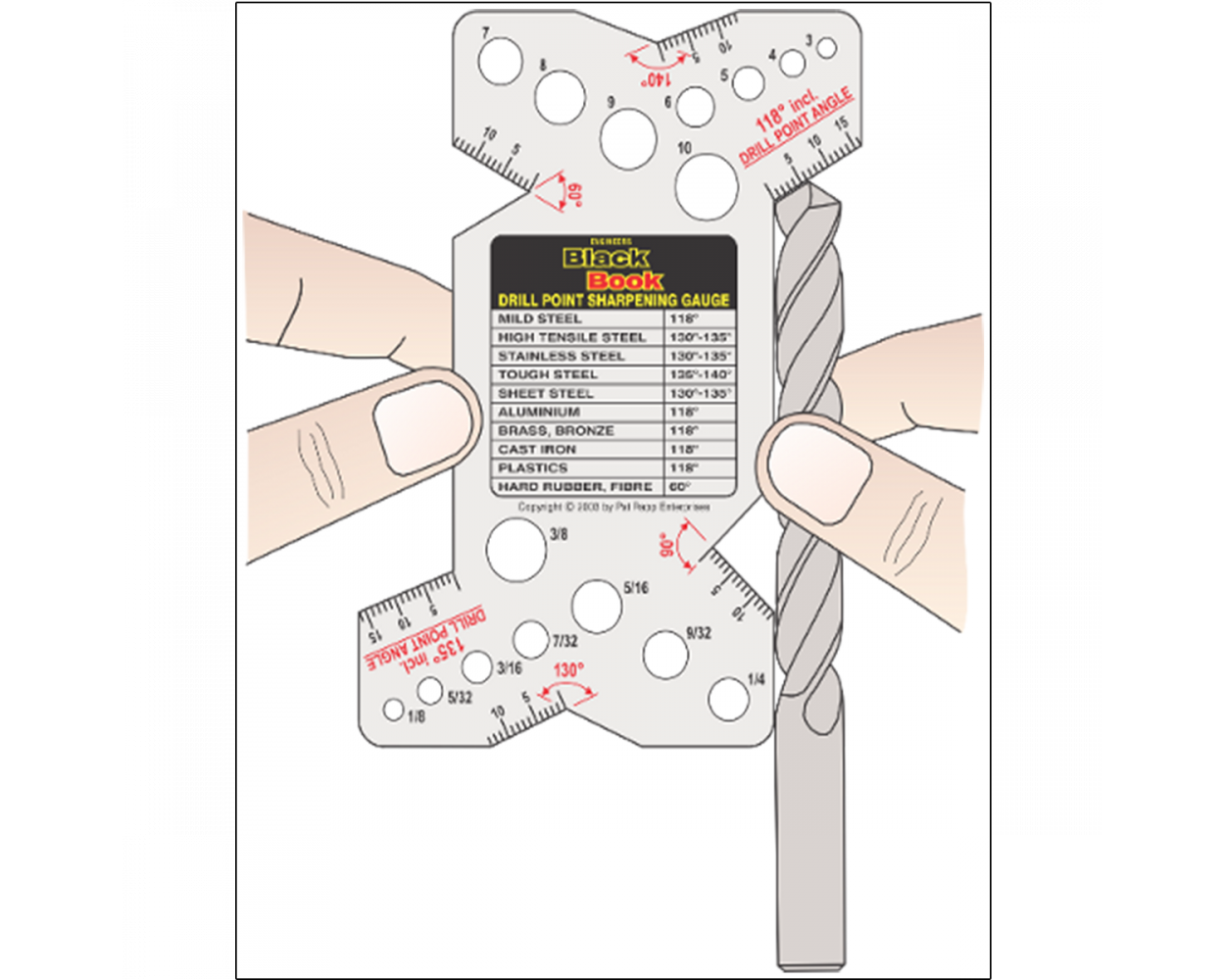

Drill Point Sharpening Gage With Imperial (Inch) Markings

ENGINEERS BLACK BOOK Drill Point Sharpening Gage

DRILL POINT SHARPENING METHODOLOGY

- Keep the drill point constantly sharp

- Avoid excessive grinding pressures

- Avoid overheating the drill point

- Avoid sudden cooling of the drill point

- Use copious supply of coolant

The periphery of the wheel should be

used for roughing-out of the drill point

if much metal must be ground away

The side of the wheel should

be used for finishing

To test whether a drill has been properly sharpened,

drill a hole in soft material and observe the chip formation.

When properly sharpened, the chips will come out of the

flutes in curled spirals of equal length

Incorrect grinding causes the drill bit to run out of true, producing oversized and often, out-of-round holes.

This puts severe strain on the drill bit causing rapid wear and premature drill failure.

Lips of EQUAL lengths but UNEQUAL angles |

Lips of UNEQUAL lengths but EQUAL angles |

Lips of UNEQUAL lengths and UNEQUAL angles |

SPECIFICATIONS

Size - Overall

80.00mm x 100.00mm

3.149" Inches x 3.936" Inches

Material

Aluminium

Thickness

0.9mm

0.0354" Inches

Hole Sizes

3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0 (mm)

1/8, 5/32, 3/16, 7/32, 1/4, 9/32, 5/16, 3/8, (Fraction)

Point Angles

60', 140', 118', 90', 130'

Weight

13.0 Grams

0.460 oz

| Price | $14.95 | |||

|---|---|---|---|---|

| Customer Service | We're Here To Help Call us anytime during our customer service hours... Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions: TOLL FREE, 800-273-7375 (Outside the U.S. call 818-887-7828). Our Address: 8001 Canoga Avenue Canoga Park, CA 91304 US Phone: 800-275-2665 E-mail: sales@buildersbook.com

| |||

| Description | ENGINEERS BLACK BOOK Drill Point Sharpening Gage DRILL POINT SHARPENING METHODOLOGY Step 1 // Hints for Hand Grinding Twist Drills

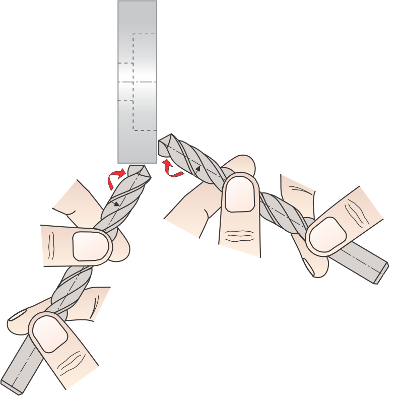

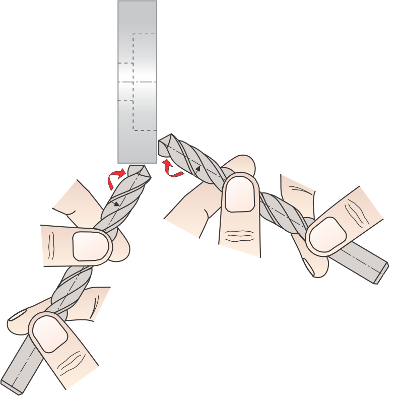

Procedure: The left hand thumb and forefinger is used as a pivot as illustrated and the back of the drill is held with the right hand and forefinger and rotated in a clockwise direction advancing the drill into the grinding wheel.

Points to Note:

Roughing

The periphery of the wheel should be used for roughing-out of the drill point if much metal must be ground away Finishing

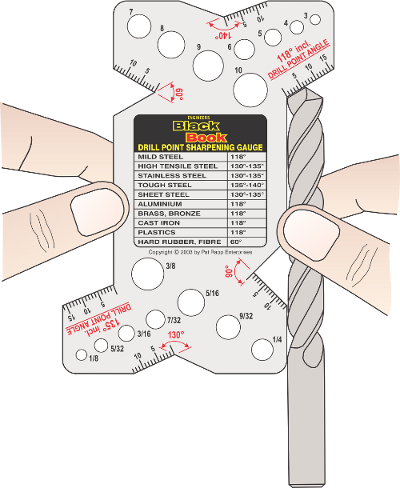

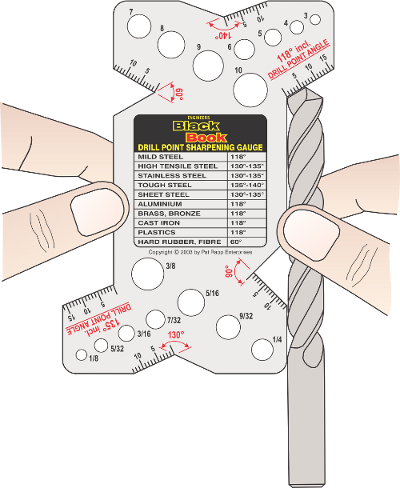

The side of the wheel should be used for finishing Step 2 // Line Drill up with Gage against desired Tip Angle

The DRILL POINT SHARPENING GAGE is the tool most frequently used to check the drill point during the sharpening operation

Step 3 // Drill Test and the Effects of incorrect grinding of the Drill Point

Size - Overall |