NFPA 79, Electrical Standard for Industrial Machinery

Help mitigate electrical hazards involving industrial machinery.

NFPA 79, Electrical Standard for Industrial Machinery, includes updates for requirements that deal with the full spectrum of equipment—from single-motored drill presses to complex automated manufacturing systems. This must-have companion to both NFPA 70®, National Electrical Code® (NEC®), and NFPA 70E®, Standard for Electrical Safety in the Workplace®, is newly revised to contend with new technologies and their effects on electrical safety. Help ensure essential protection for operators, equipment, facilities, and work in progress.

The 2024 edition includes:

- New section in Chapter 4 regarding cybersecurity considerations

- Clarification on the use of control circuit conductor protection in Chapter 7

- Metric measurements revised to soft conversions in Chapter 11 to avoid potential negative safety impact

- Removal of the term hazardous from Chapter 7 and replacement of the term conductor with wire in Chapter 12

- Revisions to the use of proximity switches and listed splicing wire connectors

- Updated Chapter 15 to clarify the application of externally supplied lighting circuit overcurrent protection

Table of Contents:

Chapter 1 Administration

1.1 Scope.

1.2 Purpose.

1.3 Application.

1.4 Specific Provisions Other Than NFPA 79.

1.5 Specific Provisions Not Made in Relation to NFPA 70.

1.6 State of the Art.

Chapter 2 Referenced Publications

2.1 General.

2.2 NFPA Publications.

2.3 Other Publications.

2.4 References for Extracts in Mandatory Sections.

Chapter 3 Definitions

3.1 General.

3.2 NFPA Official Definitions.

3.3 General Definitions.

Chapter 4 General Requirements and Operating Conditions

4.1 General Considerations.

4.2 Electrical Components and Devices.

4.3 Installation and Use of Listed or Labeled Equipment.

4.4 Electrical Supply.

4.5 Physical Environment and Operating Conditions.

4.6 Transportation and Storage.

4.7 Provisions for Handling.

4.8 Installation and Operating Conditions.

4.9 Available Fault Current.

4.10 Cybersecurity.

Chapter 5 Disconnecting Means

5.1 Machine Supply Circuit and Disconnecting Means.

5.2 Additional Disconnecting Means.

5.3 Means for Removal of Power for Prevention of Unexpected Start-Up.

Chapter 6 Protection from Electrical Hazards

6.1 General.

6.2 Basic Protection.

6.3 Fault Protection.

6.4 Protection by the Use of Protective Extra Low Voltage (PELV) or Class 2 Circuits.

6.5 Protection Against Residual Voltages.

6.6 Arc Flash Hazard Warning.

Chapter 7 Protection of Equipment

7.1 General.

7.2 Overcurrent Protection.

7.3 Overload Protection of Motors.

7.4 Abnormal Temperature Protection.

7.5 Protection Against Supply Interruption or Voltage Reduction and Subsequent Restoration.

7.6 Overspeed Protection.

7.7 Phase Sequence Protection.

7.8 Protection Against Overvoltages Due to Lightning and Switching Surges.

7.9 Power Factor Correction Capacitor Overcurrent Protection.

Chapter 8 Grounding and Bonding

8.1 General.

8.2 Equipment Grounding Conductors and Bonding Jumpers.

8.3 Control Circuits.

8.4 Lighting Circuits.

Chapter 9 Control Circuits and Control Functions

9.1 Control Circuits.

9.2 Control Functions.

9.3 Protective Interlocks.

9.4 Control Functions in the Event of Failure.

Chapter 10 Operator Interface and Control Devices

10.1 General.

10.2 Pushbutton Actuators and Color Graphic Interface Devices.

10.3 Indicator Lights and Icons of Color Graphic Interface Devices.

10.4 Illuminated Pushbuttons.

10.5 Rotary Control Devices.

10.6 Start Devices.

10.7 Devices for Stop and Emergency Stop.

10.8 Devices for Emergency Switching Off.

10.9 Displays.

Chapter 11 Control Equipment: Location, Mounting, and Enclosures

11.1 General Requirements.

11.2 Location and Mounting.

11.3 Degrees of Protection.

11.4 Enclosures, Doors, and Openings.

11.5 Spaces Around Control Cabinets and Compartments.

Chapter 12 Conductors, Cables, and Flexible Cords

12.1 General Requirements.

12.2 Conductors.

12.3 Insulation.

12.4 Conductor Markings.

12.5 Conductor Ampacity.

12.6 Conductor Sizing.

12.7 Conductors and Cables Used for Flexing Applications.

12.8 Cords.

12.9 Special Cables and Conductors.

Chapter 13 Wiring Practices

13.1 Connections and Routing.

13.2 Identification of Conductors.

13.3 Wiring Inside Enclosures.

13.4 Wiring Outside Enclosures.

13.5 Raceways, Support Systems (Cable Supports), Connection Boxes, and Other Boxes.

Chapter 14 Electric Motors and Associated Equipment

14.1 General Requirements.

14.2 Conductors Supplied from Separate Disconnecting Means.

14.3 Reserved.

14.4 Motor Dimensions.

14.5 Motor Mounting and Compartments.

14.6 Criteria for Selection.

14.7 Protective Devices for Mechanical Brakes.

14.8 Direction Arrow.

14.9 Marking on Motors.

14.10 Motor Controllers.

Chapter 15 Accessories and Lighting

15.1 Accessories.

15.2 Local Lighting of the Machine and Equipment.

Chapter 16 Marking and Safety Signs

16.1 General.

16.2 Safety Signs for Electrical Enclosures.

16.3 Function Identification.

16.4 Machine Nameplate Data.

16.5 Equipment Marking and Identification.

Chapter 17 Technical Documentation

17.1 General.

17.2 Information to Be Provided.

17.3 Requirements Applicable to All Documentation.

17.4 Basic Information.

17.5 Installation Diagram.

17.6 Block (System) Diagrams and Function Diagrams.

17.7 Circuit Diagrams.

17.8 Operating Manual.

17.9 Maintenance Manual.

17.10 Parts List.

Chapter 18 Testing and Verification

18.1 General.

18.2 Continuity of the Effective Ground-Fault Current Path.

18.3 Insulation Resistance Tests.

18.4 Voltage Tests.

18.5 Protection Against Residual Voltages.

18.6 Functional Tests.

18.7 Retesting.

Chapter 19 Servo Drives and Motors

19.1 Overcurrent Protection for Drives and Servo Motors.

19.2 Motor Overtemperature Protection.

19.3 Servo Drive System Conductors.

19.4 Contactor.

19.5 Cable Shield.

Annex A Explanatory Material

Annex B Inquiry Form for the Electrical Equipment of Machines

Annex C Examples of Industrial Machines Covered by NFPA 79

Annex D Technical Documentation

Annex E Device and Component Designations

Annex F Electrical Enclosure Ratings: Type-Rating Versus IP-Rating

Annex G Kilowatt Outputs with Horsepower Equivalents

Annex H Minimizing the Probability of Control Function Failure

Annex I AWG Conductor Cross-Reference Table

Annex J Electrical Terms Defined

Annex K Informational References

2024 (9781455931194)

2021 (9781455927296)

2018 (9781455918980)

2015 (9781455908943)

2012 (NFPA79-12)

2002 (NFPA79-02)

| Price | $209.95 |

|---|---|

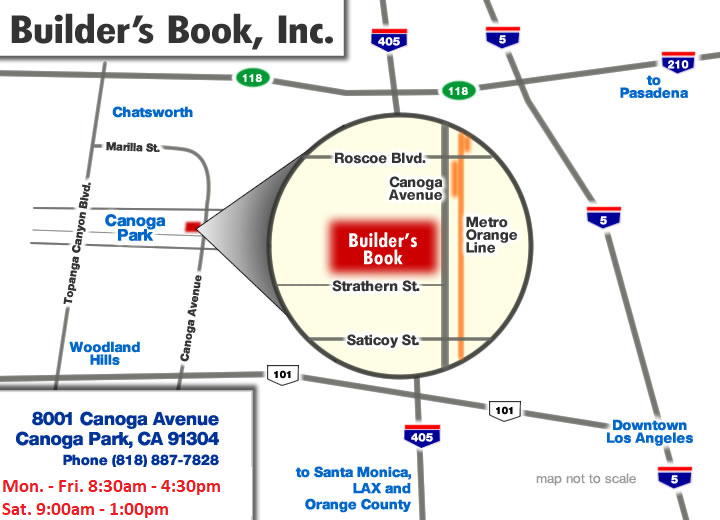

| Customer Service | We're Here To Help Call us anytime during our customer service hours... Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions: TOLL FREE, 800-273-7375 (Outside the U.S. call 818-887-7828). Our Address: 8001 Canoga Avenue Canoga Park, CA 91304 US Phone: 800-275-2665 E-mail: sales@buildersbook.com

|

| Description |

Help mitigate electrical hazards involving industrial machinery. NFPA 79, Electrical Standard for Industrial Machinery, includes updates for requirements that deal with the full spectrum of equipment—from single-motored drill presses to complex automated manufacturing systems. This must-have companion to both NFPA 70®, National Electrical Code® (NEC®), and NFPA 70E®, Standard for Electrical Safety in the Workplace®, is newly revised to contend with new technologies and their effects on electrical safety. Help ensure essential protection for operators, equipment, facilities, and work in progress. The 2024 edition includes:

Table of Contents: Chapter 1 Administration 1.1 Scope. Chapter 2 Referenced Publications 2.1 General. Chapter 3 Definitions 3.1 General. Chapter 4 General Requirements and Operating Conditions 4.1 General Considerations. Chapter 5 Disconnecting Means 5.1 Machine Supply Circuit and Disconnecting Means. Chapter 6 Protection from Electrical Hazards 6.1 General. Chapter 7 Protection of Equipment 7.1 General. Chapter 8 Grounding and Bonding 8.1 General. Chapter 9 Control Circuits and Control Functions 9.1 Control Circuits. Chapter 10 Operator Interface and Control Devices 10.1 General. Chapter 11 Control Equipment: Location, Mounting, and Enclosures 11.1 General Requirements. Chapter 12 Conductors, Cables, and Flexible Cords 12.1 General Requirements. Chapter 13 Wiring Practices 13.1 Connections and Routing. Chapter 14 Electric Motors and Associated Equipment 14.1 General Requirements. Chapter 15 Accessories and Lighting 15.1 Accessories. Chapter 16 Marking and Safety Signs 16.1 General. Chapter 17 Technical Documentation 17.1 General. Chapter 18 Testing and Verification 18.1 General. Chapter 19 Servo Drives and Motors 19.1 Overcurrent Protection for Drives and Servo Motors. Annex A Explanatory Material

2024 (9781455931194) 2021 (9781455927296) 2018 (9781455918980) 2015 (9781455908943) 2012 (NFPA79-12) 2002 (NFPA79-02) |