Working Sheet Metal

Working Sheet Metal

If you are a shop hand working with limited funds it is likely that you frequently need an article in sheet metal that you feel ill equipped to make. So here is some good news for you. It is not the equipment you lack, but rather the knowledge of how to accomplish what the equipment would do for you if you had it. Even a very small commercial sheet metal shop would have a leaf-brake, jump-shears, slip roll, bar folder, roll forming machine and a series of bench machines as a basic set-iup. This together with a bench grinder, electric drills and countless hand-tolls already totals many thousands of dollars even at second-hand prices. And workers in that shop would consider it poorly equipped. But you can produce nearly any article that could be made in that shop even though you do not own a single piece of that exotic equipment. Sheet metal equipment and machinery will cut, bend, fold, roll and otherwise shape and form sheet metal into useful articles and implements and it will do it neatly and rapidly, but the same jobs can be done by hand methods using simple devices assembled right in your shop. And much of the work can look as though it were done by a machine. Whether you want to assemble a duct system to heat and cool your home or fabricate a fuel tank for your Jeep or Dune-Buggy, the simple methods and devices in this book will enable you to do it . Sheet metal work remains a noble craft even though much of what was once made of sheet metal has been replaced by plastic. And as the plastic stuff deteriorates not long after we buy it, it won't be long before we will be making something of sheet metal to permanently replace it.

Paperback: 90 pages

Publisher: David J Gingery (1 May 1993)

Language: English

ISBN-10: 1878087134

ISBN-13: 978-1878087133

| Price | $17.95 |

|---|---|

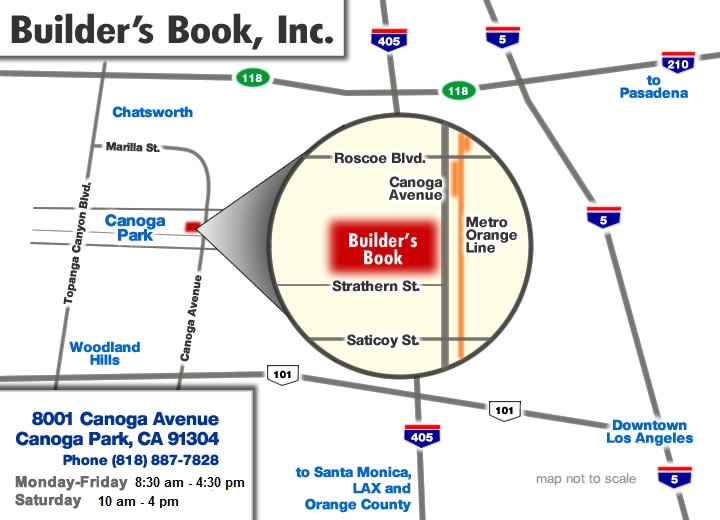

| Customer Service | We're Here To Help Monday through Friday - 8:30 am to 4:30 pm (Pacific) Order Questions: Our Address: E-mail: sales@buildersbook.com Fax Your Order

|

| Description |

Working Sheet MetalIf you are a shop hand working with limited funds it is likely that you frequently need an article in sheet metal that you feel ill equipped to make. So here is some good news for you. It is not the equipment you lack, but rather the knowledge of how to accomplish what the equipment would do for you if you had it. Even a very small commercial sheet metal shop would have a leaf-brake, jump-shears, slip roll, bar folder, roll forming machine and a series of bench machines as a basic set-iup. This together with a bench grinder, electric drills and countless hand-tolls already totals many thousands of dollars even at second-hand prices. And workers in that shop would consider it poorly equipped. But you can produce nearly any article that could be made in that shop even though you do not own a single piece of that exotic equipment. Sheet metal equipment and machinery will cut, bend, fold, roll and otherwise shape and form sheet metal into useful articles and implements and it will do it neatly and rapidly, but the same jobs can be done by hand methods using simple devices assembled right in your shop. And much of the work can look as though it were done by a machine. Whether you want to assemble a duct system to heat and cool your home or fabricate a fuel tank for your Jeep or Dune-Buggy, the simple methods and devices in this book will enable you to do it . Sheet metal work remains a noble craft even though much of what was once made of sheet metal has been replaced by plastic. And as the plastic stuff deteriorates not long after we buy it, it won't be long before we will be making something of sheet metal to permanently replace it. Paperback: 90 pages Publisher: David J Gingery (1 May 1993) Language: English ISBN-10: 1878087134 ISBN-13: 978-1878087133 |